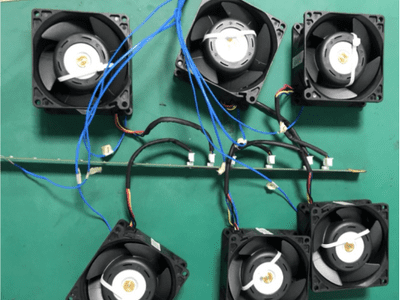

YOUR TRUSTED PARtnER FOR

COOLING FAN SOLUTIONS

CCHV Designs And Manufactures A Full Range Of Cooling Fans In Various Sizes For Different Applications, Especially High Performance DC Fan

Boost Your Product Performance with Custom DC Fan

Elevate your products with customized Cooling Fans from CCHV, tailored to your industry’s specific needs. Our versatile DC Fans optimize efficiency in various industries. Our R&D team crafts cutting-edge solutions that keep you ahead of the competition. Experience the difference of partnering with us for personalized, high-performance DC Cooling Fans designed for your success.

Renewable Energy

Renewable Energy

Home Appliances

Home Appliances

Metaverse Era

Metaverse Era

LED Lighting

LED Lighting

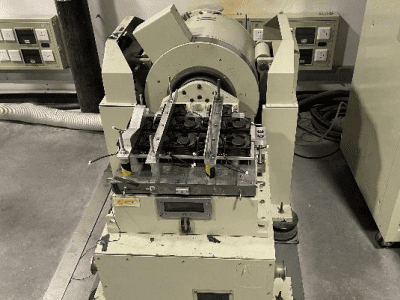

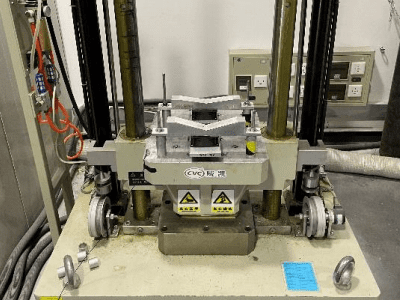

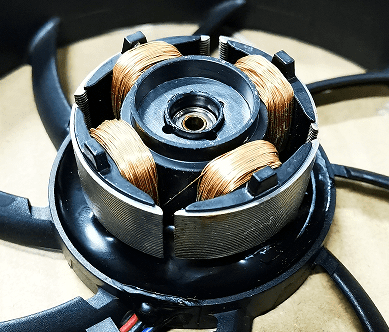

Comprehensive Fan Design Process

CCHV gets complete products development process from impeller deisgn, motor design, circuit design to reliability tests. Integrating our experienced engineers with accurate simulation softwares and advanced test equipments enable us to develop high performance, low noise and cost-effective cooling fans.

ASK FOR SUPPORT

Expert DC Cooling Fan Solutions for Your Projects: Get Started Today!

Our experienced engineers get ready to discuss and assist you to find the suitable cooling fan solutions for your application.

- 24 Hours Service: +86 - 13538992575

- Whatsapp: +86-13538992575

- Whatsapp: +86-13538992575

- Email: anniech@dcfanmfg.com

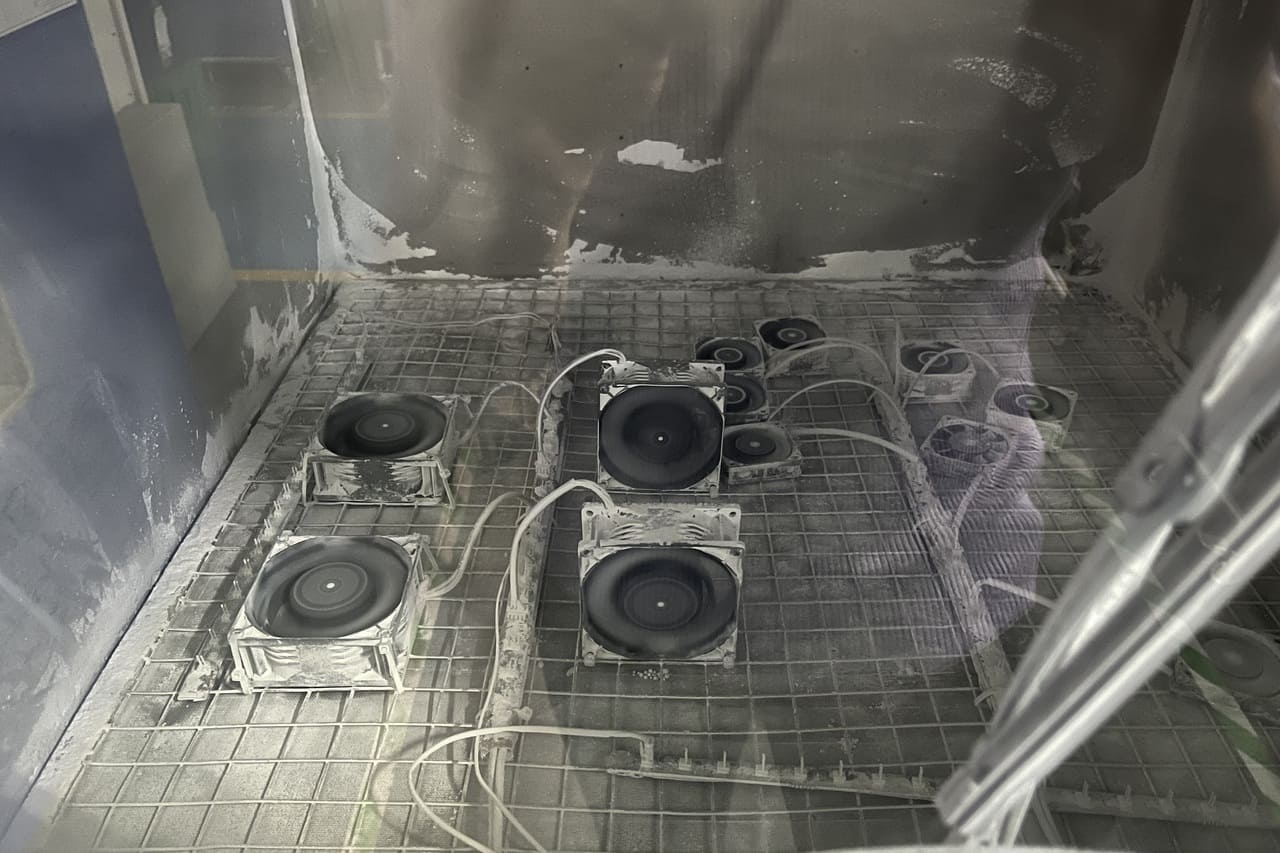

Customized Fan Testing for Enhanced Durability

To ensure our fan reliability, we seriously conduct the following comprehenstive testings. Testing conditions can be customized to ensure that our DC fans deliver consistent performance, meeting and surpassing industry standards for durability and efficiency.

01

Low Temperature On / Off Test

Test Conditions:

- High temperature: 85℃

- Power ON 15S

- Power OFF 15S

- Voltage: Input Max. Voltage

- 10000 Cycles

- Stardard: IEC 60068-2-1

02

High Temperature On / Off Test

Test Conditions:

- High temperature: 85℃

- Power ON 15S

- Power OFF 15S

- Voltage: Input Max. Voltage

- 10000 Cycles

- Stardard: IEC 60068-2-2

03

Temperture Cycling

Test Conditions:

- Low Temperature: -40℃ / 24hours

- High Temperature: +85℃ / 24hours

- Transition Time: 1 hour

- Voltage: Input Max. Voltage

- Cycles: 15 Cycles

- Stardard: IEC 60068-2-14

04

High Temperature & High Humidity Test

Test Conditions:

- High temperature: 85℃

- Humidiy: 85%RH

- Voltage: Input Max. Voltage

- Duration: 240 hours

- Stardard: IEC 60068-2-78

05

Thermal Shock

Test Conditions:

- Low temperature: -40℃ / 30min.

- High Temperature: +85℃ / 30min.

- Transition Time: Less Than 5 minutes

- Voltage: Input Max. Voltage

- Cycles:100 Cycles

- Stardard: IEC 60068-2-14

06

Vibration Test

Test Conditions:

- Directions: X, Y, Z

- Over all RMS = 3.2 G

- Frequency (HZ) & PSD (G2/HZ): 10 & 0.04; 20 & 0.01; 40 & 0.01; 800 & 0.002; 1000 & 0.002

- Duration: 2 Hours on each Director

- Stardard: IEC 60068-2-64

07

Mechanical Shock test

Test Conditions:

- Pulse Shape: Half-Sine

- Pead Acceleration: 490m/s2 (Equivalent 50G)

- Duration: 6 minutes

- Direction: X, -X, Y, -Y, Z, -Z

- 3 Shocks for Each Directiion (18 shocks in total)

- Stardard: IEC 60068-2-27

08

Lock Rotor Test

Test Conditions:

- Test Under 25℃ or Room Temperature

- Coil temperature should be monitored

- Voltage: Input Max. Voltage

- Cover with Cheese Cloth

- Duration: 72 hours

- Perform Dielectric Strength of 700Vac/10sec., and the coil temperature can not exceed 150℃. Otherwise, it's failed.

- Stardard: IEC62368-1

09

Fan Life Experimental Test

Test Conditions:

- High temperature: 85℃

- Humidiy: 85%RH

- Voltage: Input Rated Voltage

- Duration: 1230 hours

- Stardard: IPC9591

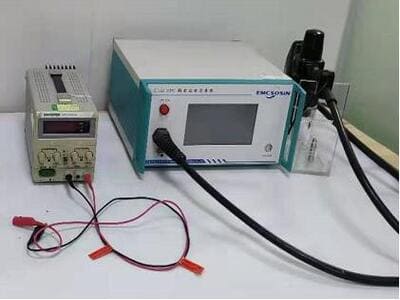

10

Electrostatic Test

Test Conditions:

- Connect ± 8KV

- Air Discharge ± 15KV

- Stardard: IEC 61000-4-2

Environmental Protection

Some parts of DC fans are used for outdoor, facing challenges against harsh enviroment, like dusty, high temperature, high humidity, corrosive, ect.. We understand the importance of environmental protection and offer different IP levels tailored to your unique needs.

IP54

Conformal Coating + PCB Gluing

(Pass 96-Hour Testing)

IP55

Conformal oating +

Whole PCB Potting

(Pass 10-Day Testing)

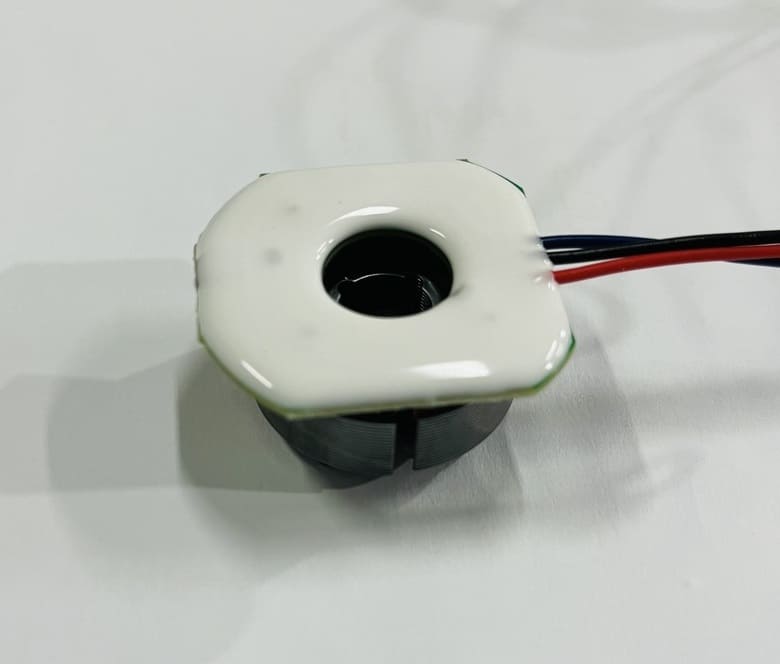

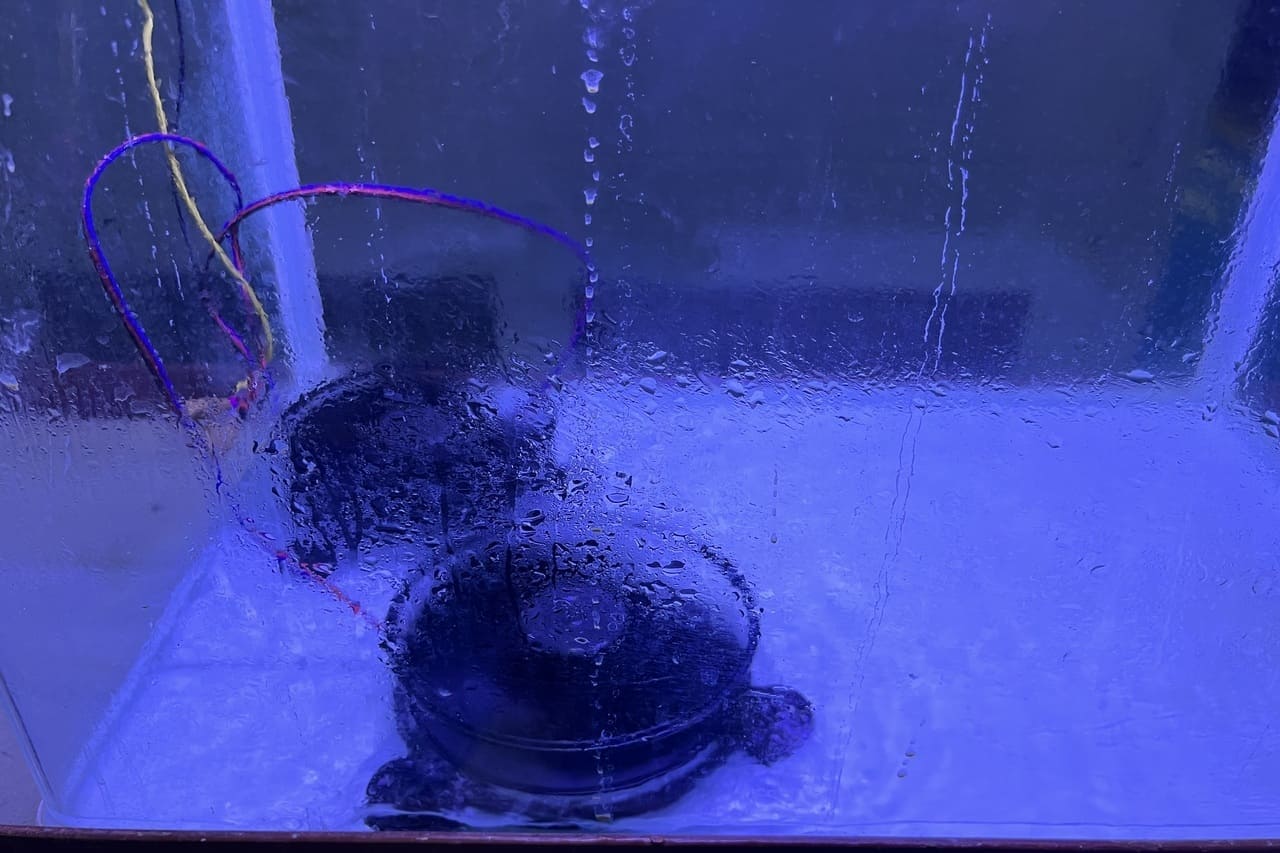

IP68

Whole Stator Coating

(Pass 30-Day Testing)

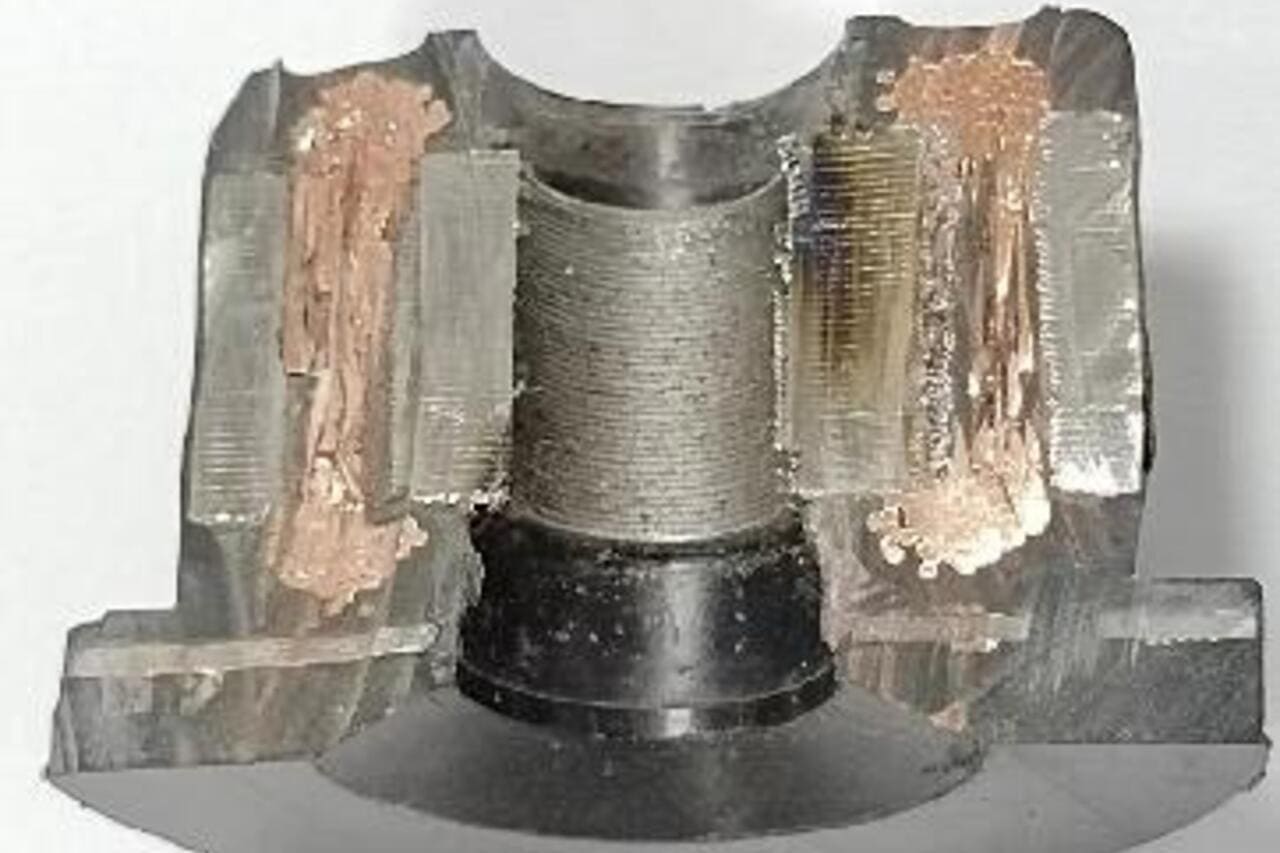

IP68 Protection Verification

01

IP68 Stator Cross Section -

Full Filled Without Porosity

02

Waterproof Test

03

Dust-Proof Test

04